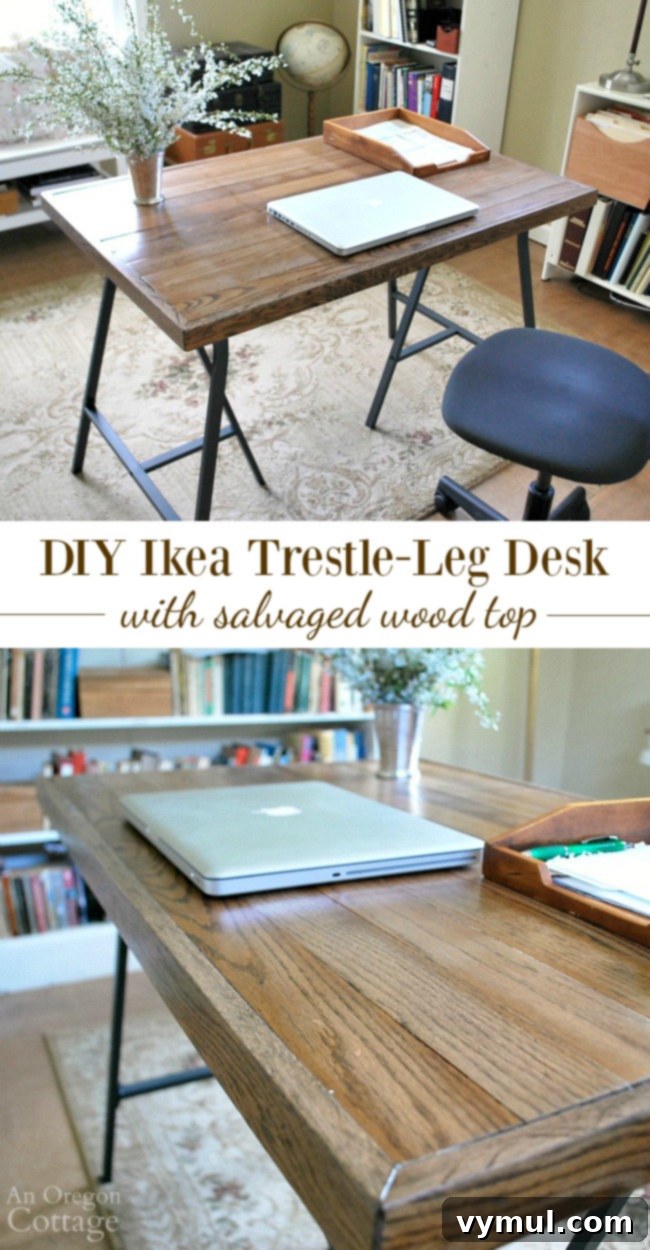

DIY Rustic Industrial Desk: Upcycle Salvaged Wood & IKEA Trestle Legs for Under $30

Embark on a creative journey to craft a stunning rustic industrial style table or desk. This comprehensive tutorial guides you through transforming IKEA trestle legs and salvaged wood flooring into a functional masterpiece, all for less than $30. Discover how easy and rewarding it is to build a custom piece that perfectly suits your home office or creative space.

Editor’s Note: This particular project was predominantly Brian’s endeavor, with Jami stepping in to finalize the desktop’s impeccable finish. We’ve managed to convince Brian to share his unique perspective and expertise as a guest post, offering valuable insights from a seasoned DIYer (albeit one who humbly claims not to be a finish carpenter!).

As someone who doesn’t consider himself a master carpenter – not even a “rough” one – it took a certain level of desperation for me to decide I needed to build a desk for my home office. Yet, what I discovered was an incredibly gratifying DIY project that proved surprisingly straightforward. By leveraging reclaimed, inexpensive materials and relying on a few basic tools, I was able to construct a desk that perfectly met my needs.

The true triumph of this entire undertaking, however, lies in the finished product. The desk boasts a captivating aesthetic, where the warmth of rustic wood meets the sleek, minimalist lines of industrial metal. Its simple styling belies its unique character, creating a focal point that is both practical and visually appealing.

The Search for the Perfect Desk & The Spark of Inspiration

My wife, Jami, had recently claimed my old desk for her own office transformation (a story for another time!), leaving me in urgent need of a replacement. All I required was a modest surface for my laptop and a few stacks of papers – nothing overly elaborate. We scoured Craigslist, frequented thrift stores, and explored countless second-hand shops in pursuit of any desk or table that would fit the bill. Time and again, we were met with disappointment. The options were either aesthetically unpleasing, structurally unsound, prohibitively expensive, or often a combination of all three. Our search felt like a Sisyphean task.

Then came our annual pilgrimage to Ikea – a 250-mile round trip that, for us rural dwellers, feels akin to a trip to Disneyland. We arrive in our trusty old Jeep, complete with a vintage 1955 utility trailer, parking ourselves amongst the other “country bumpkin” vehicles. Inside, the ritual begins: a plate of delicious Swedish meatballs, followed by a leisurely stroll as the floor arrows guide us through the vast showrooms.

On this particular visit, the arrows led us past an intriguing section dedicated to customizable furniture components. It was there that we stumbled upon a set of truly cool IKEA metal trestle legs. Priced at just $20 for the pair (the exact model is no longer available, but you can find a similar item here), they immediately caught my eye. A lightbulb moment occurred! I remembered the trove of reclaimed old wood flooring we had stored in our scrap wood shed, along with various plywood pieces salvaged from other remodeling projects. The idea solidified instantly. I turned to Jami and declared, “I’m going to make my own desk!”

This simple declaration marked the beginning of an exciting and budget-friendly DIY adventure. (Note: Affiliate links are provided below for your convenience and to help explain specific tools and materials.)

Crafting Your Custom Desk: IKEA Trestle Legs & Salvaged Wood Flooring

Building your own desk from salvaged materials offers immense satisfaction and a unique aesthetic that mass-produced furniture simply cannot replicate. This section will walk you through each step, from assembling the foundation to applying the final protective coats.

Materials & Tools You’ll Need:

- IKEA Trestle Legs (similar to NÄRSPEL)

- Salvaged Wood Flooring (enough for your desired desktop size, plus extra for edging)

- 3/4″ Plywood (for the desktop subfloor)

- 2 to 2.5-inch Bolts (depending on plywood thickness)

- Wood Glue

- 2-inch Nailing Brads

- Minwax Special Walnut Stain (or your preferred color)

- Water-Based Polyurethane (or chosen sealer)

- Regular Drill & Drill Bits

- Nail Nippers

- Hammer

- Air Nailer with Small Compressor (optional, but highly recommended for speed)

- 3 Long Wood Clamps (36 inches)

- Circular Saw

- Table Saw

- Palm Sander

- Coarse and Fine Sandpaper

- Disposable Foam Brush (for polyurethane)

- Sawhorses

- Ruler/Tape Measure

- Pencil & Sharpie

- Long Block of Wood (for tapping flooring)

- Safety Glasses & Gloves

-

Assemble Your IKEA Trestle Legs with Precision

The initial step in bringing your rustic industrial vision to life is assembling the IKEA trestle legs. While IKEA is renowned for its straightforward, diagram-based instructions, it’s still wise to proceed with attention to detail. Carefully unpack the components and lay them out. Follow each step precisely, ensuring all pieces are oriented correctly before tightening any fasteners. As Brian humorously notes, “I only put one of them together backwards and had to reassemble. It’s not their fault. The instructions are written at the chimpanzee level–you don’t even have to know how to read.” This anecdote highlights a common DIY pitfall: rushing. Take your time, double-check your work, and you’ll avoid unnecessary backtracking. These metal trestle legs will form the sturdy foundation of your desk, so proper assembly is paramount for both stability and aesthetics. Once assembled, set them aside – they’ll be ready to support your custom desktop in due course.

-

Prepare Your Plywood Subfloor

Next, you’ll need to find a suitable piece of plywood to serve as the “subfloor” for your desktop. This plywood will provide the structural integrity and a stable base for attaching the salvaged wood flooring. In my case, a piece of 3/4-inch plywood from our scrap shed, slightly larger than my target desk dimensions of 40 inches by 24 inches, was perfect. I prefer smaller desks to prevent them from becoming cluttered with excessive paperwork. The aesthetic appeal of the plywood isn’t crucial here, as it will be entirely hidden once the flooring is applied. However, it’s a good idea to give the underside a quick sanding to remove any splinters, ensuring a smooth and safe surface when the desk is moved or handled.

-

Select and Prepare Your Salvaged Wood Flooring

Now comes the exciting part: selecting the wood flooring that will define the character of your desk. Look for pieces that are longer than your desired desk length (e.g., more than 40 inches), as you’ll be trimming the ends later for a clean finish. Prioritize pieces with an attractive grain pattern and minimal damage from their previous life. The beauty of salvaged wood lies in its imperfections, but severely damaged pieces might compromise the desk’s look or structural integrity. For my 40″ x 24″ desk, I found 11 pieces of 3-inch oak flooring to be the ideal quantity, providing ample coverage and a little extra for adjustments.

-

Remove Staples from Flooring Pieces

Many reclaimed wood flooring pieces will still have old staples or nails embedded from their original installation. These need to be removed or dealt with carefully. Our wood had long flooring staples, which I quickly discovered were impossible to pull out by hammering from the back without damaging the wood. Trying to pry them out from the front with a screwdriver often leads to gouging the precious wood surface. The most effective and safest method I found was to use nail nippers (also known as end-cutting pliers). Snip the staples as close to the wood as possible. Since the bottom of the flooring will be concealed by the plywood base, a tiny remnant of the staple flush with the surface won’t be an issue.

-

Arrange and Organize Wood Flooring on Subfloor

Set your plywood “subfloor” securely on a pair of sawhorses. Identify the most square corner of the plywood – this will be your starting point for aligning the flooring. Carefully lay out your de-stapled wood flooring pieces on the plywood in the order that creates the most visually appealing pattern. Consider the grain direction, color variations, and any unique characteristics of each board. Once you’re satisfied with the arrangement, lightly number each piece on its top surface with a pencil. This simple step is a lifesaver, as pieces inevitably get mixed up during the attachment process, and you’ll want to ensure they return to their chosen positions.

-

Secure Plywood Top to IKEA Trestle Legs

This critical phase ensures your desktop is firmly attached to its industrial base. Precision here will guarantee a stable and lasting desk.

- Measure for Placement: Begin by setting up your assembled trestle legs in their intended positions. Place the plywood subfloor on top. Sit at the desk (or simulate sitting) to determine the optimal placement of the trestle legs, ensuring they are far enough inward that you won’t bump your knees on the center struts. Mark these desired positions. Then, flip the plywood onto its back and carefully place the trestle legs upside down on it, aligning them with your earlier measurements. Use a sharpie to draw a precise outline around the top crossbar of each trestle directly onto the plywood. This outline will serve as your guide.

- Drill Mounting Holes: Using a regular drill, select a drill bit sized appropriately for your bolts. Bolts between 2 to 2.5 inches are generally suitable, but adjust based on your plywood’s thickness to ensure adequate penetration without protruding too far. Drill two holes through the top crossbar of each trestle – these will be the points where you bolt the trestles to the plywood. Now, place the trestles back on the upside-down plywood, aligning them with your sharpie outlines. Use a pencil to mark through the freshly drilled holes onto the plywood. Remove the trestles, place the plywood on blocks to avoid drilling into your work surface, and drill through these marks on the plywood. The goal is for all four holes on the plywood to perfectly align with the holes on the trestle. (I can attest to the sigh of relief when they did for me!)

- Attach Securely: With all holes drilled, it’s time to firmly bolt the plywood “subfloor” onto the trestle legs. Use washers if desired for extra stability. Once tightened, carefully flip the entire assembly right side up. Your foundation is now complete and ready for the flooring application.

-

Check for Square and Position First Flooring Piece

With your bolted-down subfloor, it’s crucial to ensure your desktop will be perfectly square. Starting from the most square corner of the plywood, take your first piece of reclaimed wood flooring. Position it so that both its grooved side and its top edge are perfectly aligned with the corresponding edges of the plywood. Don’t concern yourself with the length of the flooring piece at this stage; it’s acceptable if it overhangs the plywood’s bottom edge, as this excess will be trimmed later. This initial alignment is vital for a straight and uniform desktop.

-

Attach Flooring to Plywood Subfloor

Now, let’s secure that first flooring piece. For this initial board, you’ll nail through the groove in a few places to hold it firmly, then nail from the tongue side. When nailing from the tongue side, aim the nail at an angle, as close to the edge of the tongue as possible. This angled approach ensures the nail head is recessed and won’t obstruct the next piece of flooring from sliding snugly into place. While this can be accomplished with a hammer, utilizing an air nailer with 2-inch nailing brads and a small compressor will make the process significantly faster and more consistent. (While the linked product is a well-known brand, we’ve found that inexpensive nailers from places like Harbor Freight Tools often work remarkably well for DIY applications like this desk.)

-

Install Subsequent Boards and Repeat Process

Once your first flooring piece is securely in position, it’s time to work on the remaining boards. Apply a bead of wood glue into the groove of the next flooring piece. Carefully slide this piece into place, ensuring its top surface is flush and even with the plywood subfloor. Then, using a hammer and a long block of scrap wood (hold the block against the tongue of the new board and strike the block, not directly on the tongue, to avoid damage), gently but firmly tap the board until it’s tightly seated against the previous one. Once it’s snug, nail it only on the tongue side, again angling the nails tightly to prevent them from interfering with the next board’s fit.

- Systematic Repetition: Continue this process, piece by piece, until the entire plywood subfloor is covered. You’ll find that the final piece of flooring may overhang the edge of the plywood – this is perfectly normal. To secure this last piece, nail it from underneath, but be sure to place the nails at least an inch in from the plywood’s edge. This allowance is crucial for later trimming; you don’t want your saw blade encountering a nail.

-

Clamp the Finished Top and Trim the Ends

With all the flooring laid, the desktop now needs time to set and then a precise trim for its final dimensions.

- Clamping for Curing: Before any cutting, it’s essential to allow the wood glue to fully cure. Use three long wood clamps (36 inches) to hold the entire desktop assembly tightly together. Apply even pressure across the surface. I recommend waiting a full 24 hours to ensure the wood glue has achieved maximum strength, providing a durable and cohesive top.

- Precision Cutting: Once the glue is thoroughly dry, unbolt the desktop from the trestle legs. To trim the excess wood overhanging on two sides, you’ll use a circular saw. For perfectly straight cuts, I highly recommend using the technique demonstrated in this You Tube video on how to create a perfectly straight line with a circular saw. I personally made these cuts with the back side of the desktop facing up, as shown in the video, to minimize tear-out on the visible surface. You can also view a version of this video on the blog here for easy access.

-

Prepare Finished Edges from Wood Flooring

To give your desk a professional, polished look, you’ll create finished edges using more pieces of your salvaged wood flooring. Select four pieces that are sufficiently longer than the four sides of your desk. Using a table saw, rip these pieces to a width of 1 5/8 inches. It’s important to make this cut from the side that features the tongue, as the grooved side will face downwards towards the floor and thus remain hidden from view (unless, of course, someone decides to inspect the underside of your desk with a flashlight!). This preparation ensures a clean, uniform profile for your desktop’s perimeter.

-

Edge the Desktop with Prepared Wood Pieces

With your custom edging pieces ready, it’s time to frame the desktop. Very carefully measure each side of the desk. Then, using a miter saw or miter box, make precise miter cuts (angled cuts, typically 45 degrees) on the ends of your prepared wood pieces so they form a perfect corner joint when assembled around the desk. Once cut, apply wood glue to the back of each edging piece and gently nail them around the perimeter of the table top. Use small brad nails to minimize their visibility, and ensure they are flush with the surface. This step significantly enhances the desk’s finished appearance, concealing the raw plywood edges and creating a solid, cohesive look.

Finishing Touches: Sanding, Staining, and Sealing for Durability

With the construction phase complete, the focus now shifts to the aesthetics and longevity of your desk. These finishing steps will bring out the natural beauty of the salvaged wood and protect it for years of use.

-

Thoroughly Sand the Desktop Surface

Sanding is a crucial step that transforms the raw wood into a smooth, tactile surface while preserving its unique character. Using a palm sander, start with coarse-grit sandpaper to level any minor imperfections and smooth out the initial texture. Gradually move to finer grits (e.g., 120-grit, then 180-grit, and finally 220-grit) to achieve a silky-smooth finish. This process won’t erase the charming “flaws” or unique marks of the reclaimed wood, but it will make the surface incredibly pleasant to touch. After sanding, meticulously dust off the entire surface – any lingering dust particles will show through the stain and finish. Once clean, reattach the desktop securely to your IKEA trestle legs.

-

Apply Your Chosen Stain

Now, it’s time to impart color and depth to your desktop. Following the manufacturer’s directions, apply your choice of wood stain. Jami, with her keen eye for detail, used Minwax Special Walnut, which beautifully enhances the wood grain and complements the industrial legs. Apply the stain evenly, wiping off any excess after the recommended open time to prevent blotchiness. Allow the stain to dry completely according to the package instructions. Only sand lightly with a very fine grit (e.g., 220 or 320) if the stain raises the wood grain, ensuring you follow the stain manufacturer’s guidelines for inter-coat sanding.

-

Apply a Durable Polyurethane Coating

The final step in preparing your desk for heavy use is applying a protective topcoat. Jami opted for a water-based polyurethane, which offers excellent durability, dries quickly, and is easy to clean up. For smooth, streak-free application, a disposable foam brush is highly effective. She applied four thin coats, allowing each coat to dry thoroughly between applications. After the very first coat, a light sanding with fine-grit sandpaper (e.g., 320-grit) was performed to knock down any raised grain and create an exceptionally smooth foundation for subsequent coats. Subsequent coats typically do not require sanding unless there are imperfections. This multi-coat process ensures a resilient surface that will stand up to the rigors of daily desk use, protecting your beautiful salvaged wood for years to come.

The Finished Product: A Desk Built with Character and Purpose

I’ve now been using this desk for several months, and I can confidently say it’s been a resounding success. One of my primary concerns was stability; I needed a desk that wouldn’t shake or wobble during typing, and this one delivers perfectly. It’s incredibly sturdy, a testament to the robust construction and the reliable IKEA trestle legs. While the inherent character of the reclaimed old wood flooring means the surface isn’t perfectly glass-smooth for writing directly on it, this is a minor detail for me.

I rarely write directly on a desk surface anyway, preferring to use a notebook if I need to jot something down. For my daily workflow, which primarily involves a laptop and managing documents, it’s absolutely ideal. This desk is precisely the simple, modern-rustic piece I had envisioned and searched for. It’s not just a desk; it’s a statement piece, a blend of sustainable design and industrial charm, all achieved with a modest budget and a willingness to DIY. The satisfaction of building something so functional and stylish from reclaimed materials is truly unparalleled. It’s a desk that tells a story, and it’s a story I’m proud to have created.

Ready to make your own rustic industrial desk or table? Pin this tutorial to save it for later and inspire your next project!

Disclosure: This post contains affiliate links. By clicking on these links and making a purchase, you help support AOC at no extra cost to you. We sincerely appreciate your support! Please know that we only recommend products and tools that we genuinely love and believe in. (You can always read our entire disclosure page here for more details.)