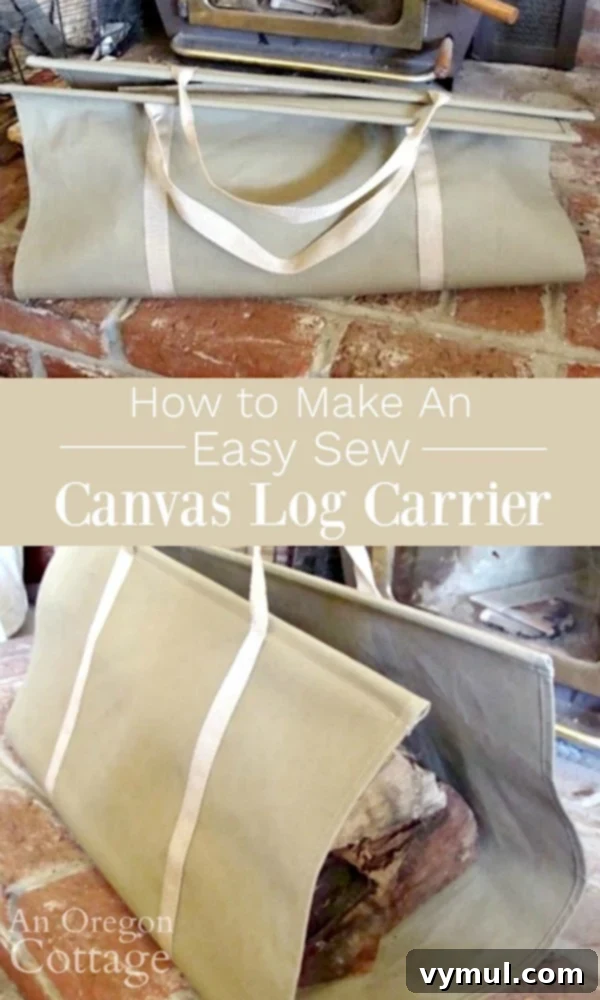

DIY Canvas Log Carrier: Easy Sewing Tutorial & Ultimate Firewood Hauler Guide

Welcome to a comprehensive guide for creating your very own canvas log carrier! This practical project is perfect for keeping your home tidy, simplifying the task of transporting firewood, and even makes an exceptional DIY gift. Far from being a complicated task, making your own log carrier is surprisingly quick, inexpensive, and requires only basic straight-stitch sewing skills.

Please note that some links within this article are affiliate links. Should you click on them and make a purchase, I may receive a small commission at no additional cost to you.

Why Every Fireplace Owner Needs a Canvas Log Carrier

There’s nothing quite like the warmth and ambiance of a crackling fire, especially during colder months. However, the joy of a fireplace often comes with the less-than-glamorous task of bringing in firewood. When we first moved into our ranch-turned-cottage, equipped with a cozy fireplace insert, we quickly realized the challenge of transporting wood without leaving a messy trail of bark, sawdust, and splinters across our floors and rugs.

Carrying logs by hand or in an old bucket not only creates a significant mess but can also be inefficient, requiring multiple trips and often resulting in dirt stains on clothes. That’s when I discovered the concept of a dedicated canvas log carrier. Seeing one advertised for around $25 one fall, I immediately recognized its potential to solve our messy firewood problem. More importantly, I realized it was a simple design that could be easily replicated as a DIY project, saving money and offering the satisfaction of a handmade item. This humble carrier can truly transform your firewood routine from a chore into a seamless part of your fire-building ritual.

The Advantages of Crafting Your Own DIY Log Carrier

Not only did I manage to make a carrier for significantly less than the retail price – roughly $6 and about an hour of my time – but I also found the process incredibly straightforward. This project requires minimal materials, a basic rectangular “pattern,” and just fundamental straight-stitch sewing. If you can sew a straight line, you possess all the skills needed to make this highly functional and attractive log carrier!

Beyond the personal satisfaction and impressive cost savings, a DIY log carrier offers several distinct advantages that make it a worthwhile project:

- Significant Cost-Effectiveness: As demonstrated, you can create a durable and functional carrier for a mere fraction of the cost of store-bought alternatives. This makes it an incredibly economical solution for anyone who regularly heats their home with wood.

- Complete Customization: Making your own allows you complete control over the aesthetics and functionality. You can choose specific canvas colors to match your home decor or hide dirt effectively, select strap colors, and even adjust dimensions to perfectly suit your log size and carrying preferences. Want a carrier made from heavy-duty, waterproof canvas for maximum protection against elements and splinters? The choice is yours.

- Superior Durability: By selecting high-quality, robust materials like heavy-duty canvas and polyester webbing, you can ensure your homemade carrier is built to withstand the rigorous demands of hauling heavy, abrasive firewood season after season, outlasting many commercial options.

- A Thoughtful and Practical Gift Idea: After crafting one for our home, I made several more as gifts for family and friends who also heat with wood. They proved to be particularly useful and appreciated presents, especially for men who can sometimes be challenging to buy for. It’s a practical item that truly gets used and admired. The personalized touch of a handmade gift always adds extra value.

- Reduced Mess and Strain: The carrier efficiently contains bark, dirt, and wood shavings, preventing them from scattering across your floor. The design also distributes the weight of the logs evenly, making it easier on your back and clothes compared to carrying armfuls of wood.

How to Make a Canvas Log Carrier: Your Step-by-Step Tutorial

This tutorial is designed with clear, visual steps to guide you through the entire process. Don’t be intimidated by the number of images or the detailed instructions; they simply illustrate how easy and straightforward each stage is. If you possess basic sewing skills – and I’m serious, just the ability to sew a straight stitch is all you need here – you will be able to create a professional-looking and highly functional log carrier with confidence.

Essential Materials for Your DIY Canvas Log Carrier Project

Gathering the right materials is the first and most crucial step to a successful project. Here’s a detailed list of what you’ll need, along with some helpful notes for selection:

- 1 yard of 58-60″ wide khaki colored cotton canvas: Khaki is an excellent and practical choice for canvas as it effectively hides dirt, ash, and grime, keeping your carrier looking cleaner for longer. However, the linked product offers a wide variety of colors if you prefer a different aesthetic to match your style or home decor. For enhanced durability, exceptional moisture resistance, and mold-proof qualities, consider using a waterproof canvas made of polyester. Alternatively, for a more rustic, rugged, or outdoor-inspired look, a camo colored waterproof canvas could be a fun and distinctive option.

- Fabric Yardage Note: This specific 1-yard amount is perfectly suited for making two carriers efficiently. By cutting the yard in half along its length, you’ll yield two pieces, each measuring approximately 36″ x 26″ (the exact dimensions may vary slightly depending on the initial width of your fabric roll). This method is both cost-effective and streamlines the cutting process. If you only need one carrier, you can purchase 3/4 yard of canvas, though you will have some leftover fabric, and it might be slightly more expensive per carrier due to less efficient cutting. A smart workaround for making a single carrier with minimal waste is to buy just 1/2 yard, cut it in half, and then sew the two smaller pieces together along their 26″ edges to achieve the desired 36″x 26″ dimension. This will create a subtle seam at what will be the bottom of your carrier, which is completely functional and often unnoticeable.

- 3 yards of 1-inch strap style webbing: You will need 3 yards of this robust webbing for each carrier, so acquire 6 yards if you plan to make two. This is the heavy-duty type of webbing typically used for tote bags, backpacks, and other items requiring strong, durable straps. I highly recommend using polyester webbing over cotton, as it offers superior resistance to abrasion, moisture, and general wear and tear, especially when carrying heavy, rough wood. The link provided offers various colors; choose one that complements your canvas fabric and, ideally, won’t easily show dirt or scuffs.

- 2 craft dowels (3/8″ x 36″) for each carrier: These dowels are not just decorative; they provide essential structure and rigidity to the ends of your log carrier. This makes it significantly easier to load wood, prevents the carrier from flopping, and facilitates comfortable carrying. While 1/4″ thickness can work, a thicker dowel (like 3/8″) will offer greater strength and stability, enhancing the carrier’s longevity and overall functionality.

- Matching polyester outdoor thread: Using polyester thread is absolutely crucial for this project. It is significantly stronger and more durable than traditional cotton thread, offering excellent resistance to rot, mildew, and UV exposure. This ensures your seams hold up reliably under heavy loads, resist moisture from damp wood, and maintain their integrity even with prolonged outdoor exposure.

- Basic Sewing Machine: Any standard sewing machine capable of a straight stitch will suffice.

- Hot Iron and Ironing Board: Essential for pressing seams to achieve crisp, professional-looking folds.

- Measuring Tape or Ruler: For accurate cutting and measuring.

- Fabric Scissors: Sharp scissors dedicated to fabric will make cutting easier and more precise.

- Pins or Fabric Clips: To hold fabric and webbing in place before sewing.

- Miter Saw or Hand Saw with Miter Box: For cutting the dowels to size.

Detailed Instructions: Crafting Your Canvas Log Carrier

Follow these steps carefully, using the accompanying images as a visual guide. Remember, patience and precision will lead to the best results!

- Prepare Your Canvas Fabric: Begin by taking your 1-yard piece of canvas fabric and cutting it precisely in half. If your fabric is 58-60 inches wide, this will yield two pieces, each measuring approximately 36″ x 26″. These dimensions are ideal for a standard log carrier. If you are only making one carrier and opted for 3/4 yard, simply cut it to the finished 36″ x 26″ size. For those using 1/2 yard, cut it in half again (you’ll have two 18″ x 26″ pieces), then sew these two pieces together along one of their 26″ edges to create a single 36″ x 26″ piece. This seam will become part of the carrier’s bottom.

- Create Durable Side Hems (Long Edges): Take one of the long 36-inch sides of your canvas piece. Fold the raw edge over by 1/4-inch and press it firmly with a hot iron. This initial fold creates a clean and even edge. Next, fold it over another 1/4-inch, completely enclosing the raw edge within the fold. Press again with the iron to set the double-fold hem in place. This technique creates a strong, neat finish that prevents fraying and ensures the carrier’s edges stand up to heavy use. Repeat this exact process for the other 36-inch long side.

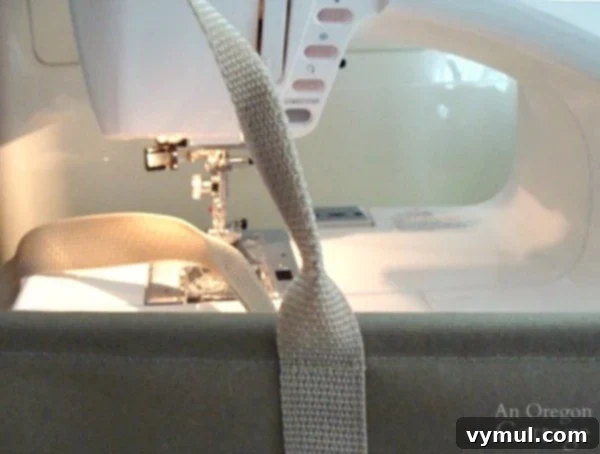

- Stitch the Side Hems Securely: Using your sewing machine and matching polyester thread, sew along the inside edge of each folded side hem. It’s crucial to “bar tack” – meaning you sew forwards and backward for the first few stitches – at both the very beginning and the very end of each seam. This reinforces the stitching, preventing it from unraveling under the constant stress and weight of firewood. Repeat this sewing process for both side hems. A helpful tip for maintaining a consistently straight stitch is to align the outer edge of your sewing machine’s presser foot with the inner fold of the hem, as clearly pictured above.

- Prepare Dowel Casings (Short Ends): With both long side hems completed, turn your attention to the two shorter, unfinished ends of the canvas. Just as you did for the long sides, fold over a 1/4-inch on each of these ends and press with an iron to create a clean initial fold. Next, to determine the precise width needed for your dowel casing, place one of your craft dowels (the 3/8″ x 36″ dowel) along this folded edge and carefully fold the fabric over it, snugly but not tightly. This visual method helps ensure a perfect fit.

- Measure and Pin Dowel Casings Precisely: Carefully measure the amount of fabric needed to comfortably encase the dowel. The key here is to create a pocket that allows the dowel to slide in and out with ease (which is incredibly helpful for cleaning the carrier or replacing a dowel, if ever needed) but is not so loose that the dowel can accidentally fall out during use. For the 3/8″ dowels I recommend, a 3/4″ hem proved to be the ideal size for a functional and secure casing. Once you have determined this measurement, remove the dowel, pin the fold at your measured mark, and press it firmly again with the iron.

- Sew the Dowel Casings: Stitch close to the inner edge of the pinned fold, creating a secure, reinforced pocket for your dowel. Ensure you bar tack at both the beginning and end of this seam for added strength and longevity. Repeat this entire process for both short ends of the canvas. These robust casings are vital for the carrier’s functionality, as they provide the structural integrity that prevents the carrier from flopping and makes loading logs significantly simpler.

- Position the Webbing Straps: Now it’s time to attach the crucial webbing straps that will form the handles of your carrier. Begin by finding the approximate middle of your canvas piece. Strategically position the webbing so that its seam (the point where the two ends of the 3-yard webbing are joined) will sit on the very bottom of the carrier once it’s finished. This placement helps to distribute the weight of the logs evenly across the carrier and keeps the handles comfortable and balanced.

- Measure and Pin the Handles for Balance: While the exact placement can be slightly adjusted to your personal preference, I found that positioning the webbing 6 inches in from each of the canvas’s long sides created the most balanced and ergonomic carry. Carefully distribute the entire 3 yards of webbing around the canvas, pinning it firmly in place as you go. Crucially, ensure that each handle loop is exactly the same length. Leave approximately 6 inches from the top edge of the canvas to the center point of where your handle will naturally sit. If you desire longer handles for easier carrying over the shoulder or a different aesthetic, feel free to increase this measurement. Finish by neatly folding 1/4 inch of the webbing end over the beginning of the webbing to create a strong, clean, and durable join.

- Verify Handle Evenness: Before proceeding with any sewing, it’s absolutely critical to double-check that both handles are identical in length and shape. Hold them together and lift slightly to simulate carrying a load. Adjust the pinning as needed until you are completely confident they will carry evenly and comfortably, preventing any awkward weight distribution.

- Secure the Webbing: Your canvas should now look precisely similar to the image above, with all webbing pinned securely in place and ready for stitching.

- Stitch the Webbing Handles Firmly: Begin sewing at the top edge of one side of the webbing. Stitch horizontally across the webbing, either just underneath or directly on top of the top edge seam of your dowel casing. Ensure the dowel pocket remains clear and unobstructed. Reinforce these top edges by sewing back and forth a couple of times; these points will bear significant pressure when the carrier is full of wood, so extra reinforcement is key to longevity.

- Continue Sewing the Straps for Durability: Turn the carrier and sew closely along the outer edge of the webbing, continuing all the way down to the other side. Turn again and sew horizontally across the webbing at the bottom, just as you did at the top, again reinforcing these stitches multiple times for maximum strength. Then, turn once more and continue stitching up the other side of the webbing, again keeping close to the edge. Repeat this entire sewing pattern for the second side of the webbing loop. This creates a box-stitch pattern on the ends, which is incredibly strong.

- Reinforce the Webbing Joint: When you reach the point where the two ends of the webbing join, sew over this joint as you normally would, ensuring the stitch covers both layers. Once the entire loop is stitched, go back and sew an additional reinforcing stitch directly across the joining seam to ensure maximum durability and prevent any unraveling.

- Enhance Handle Comfort with a Fold: To make the handles lay flatter and more comfortably in your hand, you can sew a small section of the webbing together for each handle. Start approximately one inch up from where the handle webbing attaches to the carrier body. Fold the webbing in half *towards the inside* of the handle loop. Pin at the 1-inch mark and the 3-inch mark from your starting point (relative to the attachment point). Sew firmly between these two pins, again using bar tacking at the beginning and end to securely hold the thread and the fold.

- Pro Tip for Comfortable Handles: On my very first carrier, I made the mistake of folding the entire handle over. I quickly found that this made the handle too narrow and quite uncomfortable to grip when the carrier was loaded with heavy wood. Keeping the main section of the webbing wider, with just this small folded section for improved comfort, provides a much better and more ergonomic hold, preventing hand fatigue.

- Cut and Insert the Dowels: The final step is to cut your craft dowels to the appropriate length. They should fit snugly inside their respective canvas pockets without protruding from either end, ensuring a clean finish. I used a miter saw for precision, but a simple hand saw and miter box will work just as well for this task. Don’t worry too much about making the dowel ends perfectly pretty or sanded – they will be completely hidden inside the casing, so functionality is key.

- Final Assembly: Carefully slide the newly cut dowels into their respective sewn pockets on each end of the carrier. Ensure they are fully inserted and sit flush within the casings. And just like that, your handmade canvas log carrier is complete and ready for action!

Enjoy Your Durable, Handmade Log Carrier!

See? That really was an easy and rewarding project! Since we started using our canvas log carrier, it has made a noticeable and significant difference in our daily routine. It not only keeps a substantial amount of wood debris, bark, and dirt off the rug and floor leading to our stove, but it also protects our clothing from unwanted stains, splinters, and general grime. Plus, the structured design provided by the dowels and the comfortable handles make it much easier to haul a larger quantity of wood in a single, efficient trip compared to laboriously carrying logs by hand.

Maintenance Tips for Your Canvas Log Carrier:

One of the great advantages of this canvas design is its ease of maintenance, ensuring your carrier remains functional and clean for many seasons to come. When your carrier eventually gets dirty from repeated use, simply remove the dowels from their casings. Once the dowels are out, the canvas fabric can be washed according to its material care instructions (typically cold water wash and air dry for cotton canvas). This helps prolong the life of your carrier and keeps it looking fresh.

What do you think? Is this a practical DIY project you’d like to try for your home or as a gift? Share your thoughts and any questions in the comments below!

Print

Pin

SaveSaved!

Tutorial: How To Make A Canvas Log Carrier

Tools

-

Sewing machine

-

Clothing iron

-

Measuring Tape

Materials

- 1 yard 58-60″ wide khaki colored cotton canvas (this color hides dirt more than the natural canvas – there are lots of colors, though, at that link). You could also go with waterproof canvas that’s made of polyester and is mold-proof as well, or even a camo colored waterproof canvas for fun. Fabric Note: this yardage amount makes two carriers – it’s cheapest and easiest to make two, as you just cut the yard in half to get the pattern size. If you can only think of one person who’d like this, you will need 3/4 yard of canvas, but you will have some leftover and it will be more expensive. UNLESS you don’t mind a seam in the bottom, then buy 1/2 yard, cut in half and sew together to create the 36″x 26″ piece needed.

- 3 yards 1-inch strap style webbing(for each carrier, so 6 yards to make 2 carriers), the type used for tote bags and such. I used poly (vs. cotton) to hold up to the rough handling it will get when full of wood. The link for the webbing lists many different colors – choose one to go with your fabric and not show too much dirt.

- 2 craft dowels (3/8″ x 36″) for each carrier. You can also use 1/4″ thickness, but the thicker the better with this project.

- Matching polyester outdoor thread.

Instructions

-

Cut the yard of canvas in half. You will have a 36″ x 26″ piece for each carrier (approximately, depending on the initial width of fabric). Or cut to the finished size if making one with 3/4 yard fabric, or cut in half and sew together if using 1/2 yard.

-

Make side hems. Fold over the long 36″ sides 1/4-inch, press with a hot iron, and then turn another 1/4-inch to enclose the raw edge. Press again with iron to hold seams for sewing.

-

Sew close to inside edge of side hem, remembering to bar tack (go back and forth in the first few stitches) at the beginning and the end to lock in the stitching. Repeat sewing for other side hem.

-

Make the casing (pockets) for dowels. Once both side hems are complete, turn over a 1/4-inch on each shorter, unfinished end and press with iron to hold. Measure the width needed for the casing by holding the dowel in place and folding the fabric over the dowel.

-

Measure the amount needed for dowel casing. You want enough room to easily slide the dowel in (and out for cleaning, if needed), but not so much that it will fall out on its own. I found that a 3/4″ hem was sufficient for the 3/8″ sized dowels I used.

-

Remove the dowel and pin the fold at the measurement you have before sewing in place close to the inner edge, creating the pocket for the dowel.

-

Make the Straps. Measure the placement of the webbing for the strap of the carrier. Start in the middle of the canvas, as shown, so that the webbing seam will be on the bottom of the carrier.

-

This is somewhat arbitrary, but I found that placing the webbing at 6″ in from the sides created the best balance. I then distributed the 3 yards of webbing around the canvas, (pinning as I went) making sure that each handle was the same length and ended by folding 1/4″ of the end over the beginning of the webbing to join the ends.

-

Test that both handles are the same by holding them together to be sure they will carry correctly. I did have to adjust sometimes to make them even.

-

Sew the webbing. Start at the top of one side of the webbing and then sew across the webbing just underneath, or right on top of the top edge seam (to leave pocket free for the dowel). Sew back and forth a couple of times to reinforce these top edges, as they will get a lot of pressure when carrying wood.

-

Turn the carrier and sew close to the edge of the webbing all the way to the other side, turn again and go across just like the other end (again reinforcing a couple of times), and then turn and continue up the other side, again close to the edge. Repeat for the other side of the webbing.

-

When you come to where the webbing joins, sew over the joint like normal, but come back when you’re finished and sew across the joining seam to secure.

-

To help the handles lay better where the webbing meets the tops of the holder, sew a little bit of the webbing together for the handle as shown in the photo above. Start about an inch up from where you sewed the handle to the carrier, and fold the webbing in half towards the inside

-

Pin at the 1-inch mark and the 3-inch mark and sew between these pins, tacking back and forth at the beginning and the end to hold the thread.

-

TIP: On the first carrier I made, I folded the entire handle over but found it made the handle too narrow, making it uncomfortable to carry when loaded with wood. The wider webbing is much easier to hold.

-

Cut the dowels. The last step is to cut the dowels to the length needed to fit inside your dowel pocket without showing on either end. I used a miter saw, but a hand saw and miter box would work as well.

-

Insert the dowels and you’re done.

This comprehensive tutorial was originally published in April of 2011 and has since been updated to provide even clearer instructions and additional insights for an improved crafting experience.

Disclosure: Affiliate links in this article are provided for your convenience and may earn a commission based on sales, without affecting your purchase price. Click here to read my full disclaimer and advertising disclosure for more information.