Mastering DIY Floating Floors: An Easy & Affordable Room Transformation

Welcome to another exciting home renovation reveal! After years of dreaming and planning, we’re thrilled to finally unveil the stunning transformation of our master bedroom floor. What started as a vision for an easy, impactful, and budget-friendly update has culminated in a beautiful DIY floating engineered hardwood floor that has completely revitalized our space. This isn’t just a simple flooring change; it’s a testament to how a focused Saturday of effort can yield dramatic results, proving that a significant home upgrade doesn’t always require extensive time or a hefty investment. Get ready to see the dramatic before and after photos of a DIY floating floor, an update that truly makes a big impact in a short amount of time.

I am participating in a sponsored campaign hosted by Advil®. I received compensation for this post. All opinions stated are my own.

The Appeal of Floating Floors and Our DIY Journey

For seasoned DIY enthusiasts like us, tackling various flooring projects has become a hallmark of our home improvement journey. We’ve experimented with almost every conceivable type of DIY floor – from the rustic charm of painted plywood and stained plywood, to the unique aesthetic of brown paper with polyurethane. Our past endeavors also include the intricate process of laying reclaimed wood floors and even the notoriously challenging task of tiling (a feat I’ve vowed never to repeat!). Through all these experiences, our primary goal has consistently been to replace unsightly and unhygienic carpeting with durable, beautiful alternatives.

Among all these methods, installing a DIY floating floor stands out as arguably the simplest and most efficient. The most significant advantage, which dramatically speeds up the renovation timeline, is that floating floors come prefinished. This means there’s no tedious waiting period for stains to dry or protective topcoats to cure, a process that can easily add a week or more to traditional flooring projects. Instead, you lay them down, and they’re ready to enjoy almost immediately. This characteristic alone makes them incredibly appealing for those seeking a quick yet impactful update. We even shared our top tips for laying a floating floor to help make your project even smoother.

Understanding Floating Floors: Pros and Cons

While the ease and speed of floating floor installation are undeniable, it’s also important to consider their specific characteristics. Floating floors, by definition, aren’t directly attached to the subfloor. Instead, they ‘float’ over it, often with a thin foam underlayment for cushioning, moisture barrier, and sound absorption. This design contributes to a slightly different feel underfoot; some describe it as having a minor ‘bounce’ or a less solid sound compared to traditionally nailed or glued-down hardwood. Furthermore, due to their construction and often thinner wear layer (especially with engineered options compared to solid hardwood), they typically cannot be refinished multiple times. This means that while they offer excellent durability for everyday wear, severe damage might necessitate replacement rather than restoration.

However, for our particular needs and priorities – namely, an easy, quick, and cost-effective transformation – these potential drawbacks were far outweighed by the numerous advantages. The ability to install a beautiful, durable floor in a single weekend, without the mess and drying times associated with other methods, made floating engineered hardwood an ideal choice for our master bedroom. Its aesthetic appeal, combined with straightforward installation and a friendly price point, makes it a top contender for any homeowner looking for a significant upgrade.

Our Master Bedroom: The “Before” Story – A Paper Floor Predicament

Our master bedroom had been living with a flooring dilemma for several years. After successfully tearing out the old carpeting (a personal crusade in all our homes!), we opted for a DIY brown paper floor – a technique we’d executed successfully five times before in other rooms. This method involves tearing and crumpling brown builder’s paper into unique shapes, then gluing them to the subfloor and sealing with polyurethane, creating a faux leather-like texture that’s incredibly charming and budget-friendly, typically costing around $100 per room. We absolutely adored the results in our kids’ rooms, where the texture resembled aged leather, adding character and warmth.

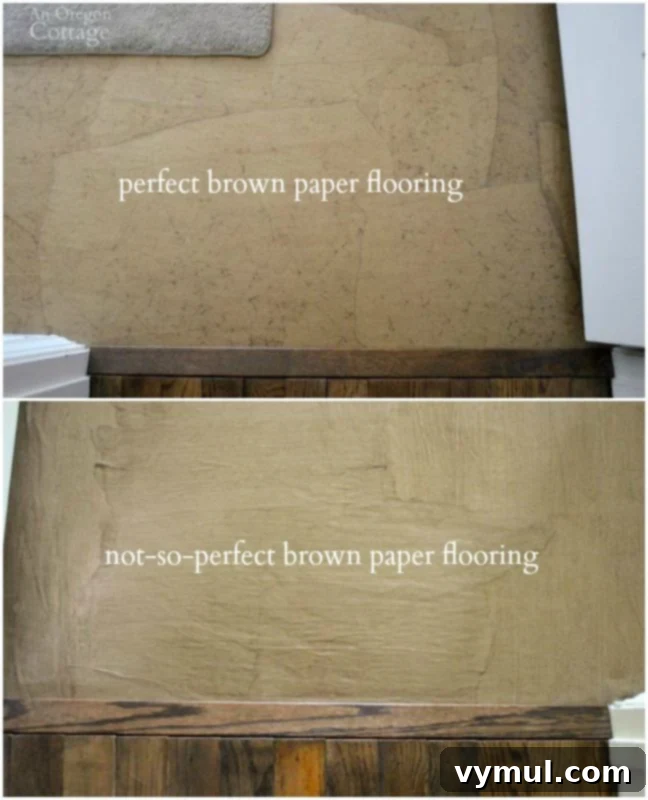

To give you an idea of the intended effect versus what we unfortunately achieved, here’s a side-by-side comparison:

As you can clearly see, part of the brown/kraft paper floor technique is to crumple the paper after tearing it into shapes before gluing down to the subflooring. This creates the cool, organic texture you see in the top picture – a rich, faux leather look that is a really fun, creative, and inexpensive way to get rid of carpet. However, our sixth attempt in the master bedroom, shockingly, did not go as planned. I later discovered that the batch of brown builder’s paper I purchased this time was significantly thicker than what I’d used previously. This seemingly minor difference had a profound impact: the paper wouldn’t crumple effectively, and consequently, the signature texture that defines this technique was entirely lost.

What we ended up with was a flat, uninspired surface that, frankly, looked like paper simply glued to the floor – a far cry from the intended faux leather aesthetic. I kept hoping the texture would miraculously appear as it dried, but it never did. Desperate to salvage the situation, I even tried adding some stain to the polyurethane topcoat, which offered only a minimal improvement. At this point, the project had consumed an exorbitant amount of time and emotional energy – I’m talking over a week, complete with a few tears! A critical misstep early on led me to accidentally use an oil-based poly, forcing me to tear up the first coat after mistakenly using an oil-based poly and start over. My muscles were screaming, and I was in desperate need of a pain reliever like Advil® just to cope with the physical strain and frustration. We decided then that we simply had to live with it until we could commit to a proper flooring replacement.

From Frustration to Freshness: The Floating Floor Solution

The memory of that frustrating paper floor experience made us even more determined to find a reliable, beautiful, and straightforward solution for our master bedroom. We often receive inquiries about how to transition from a paper floor to another type of flooring, as it’s a popular interim option. Our experience here provides the perfect answer: there’s absolutely no need to remove the existing paper floor if it’s applied directly to the subfloor. This was a huge relief and significantly streamlined the preparation process for our new engineered hardwood. While we still love our paper floors when done correctly in other rooms and have no plans to cover them, for the master bedroom, a change was essential. With the decision made and our chosen engineered hardwood planks in hand, we were ready to embark on a weekend project that promised to erase the memory of past flooring woes and usher in a fresh, elegant aesthetic. As you can see, the new engineered hardwood look is vastly superior to the not-so-perfect paper floor, offering a sophisticated upgrade.

Installation Insights: Overcoming Challenges & Achieving Results

Embarking on the DIY floating floor installation, we were prepared for a full day’s work, but the process unfolded with surprising efficiency, largely thanks to the excellent tips we followed. One of our main concerns revolved around our existing board-and-batten wall treatment, which we added back when we started our remodeling. This beautiful feature meant that removing the baseboard molding was not an option, as it would necessitate dismantling all the battens – a scenario we were determined to avoid. Fortunately, engineered hardwood flooring typically measures between 5/16th to 3/8th of an inch thick. This relatively slim profile meant it wouldn’t significantly alter the appearance of our existing molding. To bridge the small gap between the new floor and the baseboards, we simply added painted quarter-round shoe molding. This subtle addition seamlessly finished the edges, making the transition virtually unnoticeable and preserving the integrity of our beloved board-and-batten design.

The click-and-lock system (or in some cases, tongue-and-groove with glue, as we used for added stability) of floating floors is incredibly user-friendly, allowing each plank to be snugly fitted against its neighbor. We also laid foam floating floor padding first to provide a comfortable underlayment and sound dampening. The prefinished nature of the engineered hardwood was, again, a game-changer; as soon as the last plank was laid, the room was instantly transformed and ready for furniture. This project truly reinforced our belief that floating floors are the most approachable DIY flooring option for homeowners looking for a professional-looking finish without the professional price tag or the arduous labor of other methods. It’s a clean process with quick gratification.

The “After” Reveal: A Stunning Aesthetic Upgrade

The moment we stepped back to admire the finished floor, the transformation was undeniable and deeply satisfying. We carefully selected a darker finish for our engineered hardwood, specifically chosen to complement the existing flooring throughout the rest of our home, ensuring a cohesive and elegant flow. The rich, deep tones of the new floor create a beautiful contrast with our lighter walls and furniture, instantly infusing the master bedroom with a sense of sophistication and warmth. This contrast adds a perceived depth and elegance that was entirely absent before. Of course, with darker floors, the question of dust often arises. And yes, I’ll be completely honest: dust bunnies do tend to make more of an appearance against the dark backdrop. However, it’s a minor trade-off that we are more than willing to accept for the sheer beauty and upgraded feel the floor brings to our most private sanctuary. The visual impact is simply stunning, turning a previously problematic space into a highlight of our home.

Budget & Practicalities of Your DIY Floating Floor

One of the most appealing aspects of this renovation was its remarkable affordability. We pride ourselves on finding smart solutions that don’t break the bank, and this floating floor project was no exception. By patiently searching for sales, we managed to secure high-quality engineered hardwood at an excellent price, proving that a high-impact room makeover doesn’t have to be expensive.

While the financial investment was manageable, it’s important to remember that any significant DIY project, especially one involving moving furniture and working on your hands and knees, can take a physical toll. We’ve learned through our DIY flooring projects that there’s no way to avoid all the up-and-down movements over many hours that cause you to use muscles you didn’t know you had. This plus the fact that you need to move the furniture out and back in means we like to use Advil® in the aftermath of projects like this and we always have some in the cupboard. We suspect many fellow DIYers can relate to this essential recovery strategy!

Budget Breakdown:

- 180 square feet of engineered hardwood flooring at $2.49/sq. ft. (we found a good deal!): $456

- Foam floating floor padding (2 rolls): $50

- 2 bottles wood floor glue: $16

- Quarter round molding: $25

- Threshold pieces (used pieces already had)

- TOTAL: $546

(Paint: ‘Creamy White‘ by Behr)

So, what do you think of our master bedroom’s dramatic transformation? We are absolutely thrilled with how this DIY floating engineered hardwood floor turned out. It perfectly balances durability, aesthetic appeal, and budget-friendliness. The search for flooring that had a genuine hardwood look, without any artificial ridges or an overly ‘fake’ appearance, was successful. We truly believe we found the perfect balance of authenticity and modern practicality. This project proves that with a little research, some elbow grease, and the right materials, you can achieve a high-impact room makeover that looks professionally done, all within a reasonable budget and timeframe. We hope our before-and-after journey inspires you to tackle your next home improvement project!

Disclosure: I received product and/or compensation for this post. As always, the opinions, thoughts, and projects are all mine and I will NEVER promote something I don’t love and think you will find helpful – promise! For more info, you can read our entire disclosure page here.