Mastering DIY Floating Floor Installation: Your Comprehensive Guide to a One-Day Room Transformation

Revamp any room in a single day with the magic of engineered hardwood or laminate floating floors. This guide is packed with expert tips and tricks designed to make your installation process smoother, faster, and remarkably easy. Get ready to transform your space with confidence and achieve professional-looking results without the hassle.

As a participant in a sponsored campaign hosted by Advil®, I received compensation for this post. All opinions and experiences shared are genuinely my own.

I am absolutely thrilled to share a recent DIY triumph with all of you – the installation of a beautiful, prefinished engineered hardwood floating floor in our master bedroom! My excitement isn’t just about the stunning aesthetic transformation (though it truly looks fantastic!), but also about how incredibly straightforward and non-disruptive the process turned out to be. Believe it or not, this significant home improvement project was completed from start to finish in just one day!

Through this hands-on experience, we discovered several clever strategies to simplify the floating floor installation process, making it accessible even for novice DIYers. I’ll be detailing these invaluable tips across two posts. This first part focuses entirely on the practical advice for laying your own floating floor, equipping you with everything you need to know for a successful project. Following this, I’ll share the complete “before-and-after” reveal of the master bedroom, showcasing the dramatic impact of this upgrade. So, definitely stay tuned for that!

Choosing Your Flooring and Essential Materials

Our engineered hardwood flooring was sourced from a trusted local home improvement store. While it didn’t carry a prominent brand name, its rich color and exceptional value (at just $2.49 per square foot) made it the perfect choice for our needs. A key feature we appreciated was its smooth finish, lacking the “wavy grooves” often found in many engineered hardwood samples. This oak flooring genuinely looks and feels like authentic oak, albeit with a slightly smoother texture than traditional solid oak. Any type of floating floor that relies on adhesive for plank adhesion (rather than nails or staples) will be compatible with these DIY techniques, including many laminate options.

Beyond the flooring itself, the material list was surprisingly minimal. We purchased a high-quality flooring foam underlayment, crucial for sound dampening and moisture protection, and two bottles of a specialized wood glue formulated specifically for flooring applications. Selecting the right materials upfront is the first step to ensuring a smooth and lasting installation.

Pre-Installation Preparation: The Foundation for Success

Before you even think about laying your first plank, proper preparation is paramount. Rushing this stage can lead to frustrating issues down the line. Begin by completely clearing the room of all furniture, rugs, and any existing flooring if you’re replacing it. Ensure the subfloor is clean, dry, and free of debris. Use a vacuum cleaner to remove dust and dirt, and inspect for any lingering moisture.

It’s also vital to allow your new flooring to acclimate to the room’s environment. Unpack the boxes and stack the planks in the installation area for at least 48 to 72 hours prior to installation. This allows the wood or laminate to adjust to the room’s temperature and humidity levels, preventing potential expansion or contraction issues after installation. Finally, assess the subfloor for levelness. Minor imperfections can often be remedied with a self-leveling compound or by sanding down high spots. While not always necessary, removing existing baseboards can simplify the installation process and provide a cleaner finish, though our method offers an alternative if removal isn’t desired.

DIY Tips For Laying Floating Floors

Our initial journey was a bit challenging due to confusing, contradictory directions included with our flooring. This led us to seek better guidance online, where we discovered this exceptionally helpful video from Lowe’s. We highly recommend watching it before embarking on your project. Beyond that, here are some additional insights and tools we found to be incredibly valuable (affiliate links included for your convenience):

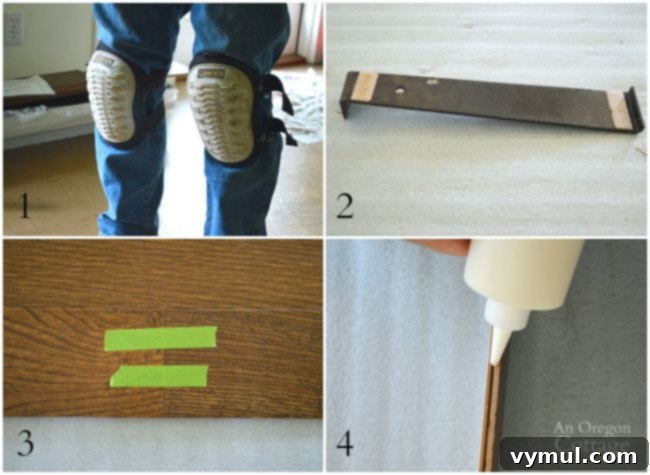

1. Don’t Skimp on Quality Knee Pads

This is arguably our most crucial comfort-related tip. Investing in a sturdy, comfortable pair of knee pads is non-negotiable. You will spend a significant amount of time on your knees during this project, and cheap, ill-fitting pads will quickly become more of a hindrance than a help. Look for pads with thick cushioning, adjustable straps, and a design that stays in place. Your knees will thank you, allowing you to work longer and more efficiently without debilitating pain.

2. The Lifesaving Flooring Pull Bar

A simple yet revolutionary tool, the flooring pull bar proved to be an absolute lifesaver. Our friend brought one, and it quickly became indispensable. This tool is designed to help you tighten planks along the wall edges, especially when you’re working in tight spaces where your hands or a tapping block won’t fit. It allows you to leverage the wall to pull the last plank into a snug fit, ensuring perfectly tight seams across your entire floor. Do yourself a favor and add this to your toolkit.

3. The Versatility of Painter’s Tape

We found painter’s tape to be surprisingly useful in several instances while the glue dried. It’s a fantastic, low-tack solution for holding newly laid planks together, preventing any shifting or gapping as the adhesive cures. This tip, gleaned from the aforementioned video, proved invaluable for maintaining tight seams and ensuring the floor remained perfectly aligned during the critical drying period. It can also be used to mark cuts or hold smaller pieces in place temporarily.

4. Precision Glue Application is Key

When it comes to applying glue, the right bottle makes all the difference. Make sure to purchase flooring glue in a bottle equipped with a pointed applicator tip. This design facilitates quick and easy application. We learned two critical lessons here: first, cut the glue tip as small as possible to ensure you apply only a narrow, consistent bead of glue along the plank’s tongue. Second, always keep a moist rag readily accessible. Immediately wipe up any excess glue that seeps out from the cracks between planks. Catching it right away prevents it from drying on the floor surface or being accidentally spread to other areas by your shoes, saving you significant cleanup effort later.

5. Achieving Consistent Expansion Gaps with Spacers

Laying the first row of boards, and indeed maintaining proper spacing throughout, is crucial for a floating floor. We devised a brilliant, cost-effective trick for maintaining perfectly even expansion gaps: use paint sticks. These are readily available and often free from paint stores. Cut the sticks into fourths and place them along the wall edges to hold the flooring at a consistent distance from the wall. This expansion gap is vital as it allows the flooring to expand and contract naturally with changes in temperature and humidity, preventing buckling or warping. Pay extra attention to placing these spacers at board joints for maximum stability. You can also purchase specific flooring spacers, but paint sticks work just as well and save money.

6. The Power Duo: Rubber Mallet and Scrap Wood Block

For creating those satisfyingly tight seams between planks, two tools are indispensable: a rubber mallet and a simple scrap piece of wood. The technique is straightforward but effective: hold the scrap wood block against the edge of the plank you’re installing, then gently but firmly tap the wood block with the rubber mallet. This action drives the plank snugly against its neighbor without directly impacting the flooring’s delicate edges, which could cause damage. Apply this method to both the long sides and the shorter ends of the planks to ensure every seam is perfectly closed, contributing to a professional and durable finish.

7. Prioritizing Your Well-being: Managing DIY Aches and Pains

Let’s be honest, DIY projects, especially flooring installations, involve a considerable amount of physical exertion. There’s no escaping the constant up-and-down movements, bending, lifting, and repetitive actions. That’s why another essential item we always keep on hand for our home improvement endeavors is Advil® – for reliable relief from the inevitable aches and pains that come with such projects.

While Advil® is a proud sponsor of this post, I want to emphasize that my endorsement is entirely genuine. It’s one of the reasons I was so happy to partner with them, as it’s a product we truly use and trust in our household. Years ago, my physical therapist sister recommended it for severe back pain I was experiencing, and it has since become a staple in our DIY first-aid kit because it consistently delivers effective relief. Taking a proactive approach to managing discomfort allows you to stay focused and productive throughout your project. Remember to take breaks, stretch, and listen to your body.

(As a side note, this photo humorously illustrates the importance of tip #1. You can see Brian, our intrepid installer, learned the hard way about subpar knee pads by starting the project with a pair that kept slipping down. Thankfully, his friend Dan came to the rescue with a proper pair, allowing him to comfortably finish the job!)

8. Mastering Precision Cuts for a Professional Finish

As you near the final stages of your flooring project, you’ll inevitably encounter spaces that are too small for full-sized boards. This is where precise cutting becomes paramount, and honestly, it’s often the trickiest part of the entire installation. For these crucial rip cuts (cutting planks lengthwise), we found that borrowing, renting, or purchasing a table saw was virtually the only effective way to achieve accurate, straight cuts that fit perfectly. While we’re not professional woodworkers, it’s challenging to envision completing these narrow cuts without one. For the end pieces of each row, which are crosscuts, we used a powered miter saw (also known as a “chop saw”), though a handsaw with a miter box could also suffice for these cuts.

Another invaluable tool that saved us immense time and effort was an oscillating multi-tool/saw. We used it to undercut the bottom of our door moldings, allowing the new flooring to slide neatly underneath without the need to remove and reinstall the entire door casing. This was particularly beneficial for us since we weren’t removing the existing baseboard molding due to our room’s board-and-batten wall treatment, which would have been a much more complex task. Proper tool selection and safe operation are essential for achieving a polished look and avoiding costly mistakes.

9. Pre-Finishing Your Trim for a Speedy Conclusion

Our final, highly recommended tip is to have all your finishing pieces painted or stained and thoroughly dried before you even start laying your floor. We opted for quarter-round molding to cover the expansion gaps at the baseboards. By having this molding primed, painted, and completely dry ahead of time, we were able to nail it into place immediately upon finishing the floor installation. This foresight significantly streamlines the final stages of the project, allowing you to quickly put your room back in order and enjoy your newly transformed space, often within that same single day! It’s a small step that yields huge time-saving benefits and contributes to a professional, cohesive look.

Bonus tip: For any exposed, cut edges of the quarter-round molding, use a small artist’s paintbrush to meticulously touch up the paint or stain in place. This provides a flawless finish without needing to remove the trim.

We are absolutely loving the results of our new engineered hardwood floor – and how surprisingly easy and satisfying this entire project turned out to be! Stay tuned for our next post, where we’ll reveal the complete before-and-after transformation of the master bedroom, showcasing the stunning impact of this DIY upgrade.

Disclosure: I received product and/or compensation for this post. As always, the opinions, thoughts, and projects shared are entirely my own, and I will NEVER promote anything I don’t genuinely love and believe you will find helpful – that’s a promise! This post also contains affiliate links; by clicking on them, you help support AOC at no extra cost to you! For more information, you can read our entire disclosure page here.